Our roads are seeing more and more vehicles that run on natural gas, whether in its compressed (CNG) or liquefied (LNG) form. Just like gasoline or diesel vehicles, appropriate maintenance is essential to ensure their optimal lifecycle.

What is the design of mechanical facilities for these new vehicles? Currently, Canada and Québec have no codes with the obligatory nature of law that specify the requirements for the inside installations, storage and cargo handling for natural gas vehicles.

However, many codes and publications cover the subject. In this article, we will present the principal requirements specified by some American and international standards, as well as by various authorities such as Natural Resources Canada and the Canadian Natural Gas Vehicle Alliance (CNGVA).

General considerations

First, unless otherwise indicated by the owner, natural gas vehicles are permitted everywhere where gasoline or diesel vehicles are authorized, including underground commercial and residential parking. They can travel through tunnels and no qualification card is required for filling them. Vehicles must show no leakage of fuel before entering a covered parking lot.

The maintenance or repair of components of a fuel (natural gas) supply system must be carried out by a mechanic holding the appropriate competency certificate1 from the Ministère de l’Emploi et de la Solidarité sociale (Emploi Québec).

Design of facilities and types of repairs offered[M4]

It is important to differentiate between the design of minor repair garages and those doing major work. The NFPA 30A code thus exempts minor repair garages from restrictions regarding any modifications to natural gas vehicles. However, the installation of methane detectors connected to a visible and audible alarm is recommended. Minor repairs include, but are not limited to, the following:

- lubrication;

- inspection and minor maintenance work, such as engine tune-ups;

- replacement of parts;

- draining oil, antifreeze, transmission and brake fluids, air-conditioning coolants, etc.

- repairs to the brake system;

- tire rotation;

- and other similar routine maintenance work.

Major repairs usually require a timeframe of 8-12 continuous hours of work. They may, for example, include the following:

- engine overhaul;

- painting;

- bodywork;

- welding or grinding work;

- repairs that require draining the vehicle’s fuel tank.

Another important consideration is the prolonged presence of LNG vehicles. Since the LNG is contained in a non-refrigerated tank, when the tank is exposed to the ambient temperature, it warms the LNG and the vapour pressure inside the tank increases. This pressure is managed by an overpressure valve that may release a certain quantity of odourless natural gas in the mechanical garage.

Mechanical garages where major work is carried out near natural gas vehicles therefore need to be adapted accordingly.

The rest of this article covers the changes that need to be made to mechanical garages where only major work is performed.

Mechanical garage for major work

General considerations

The type of ceiling is very important and must not be overlooked since, in case of a leak, the natural gas must not be trapped in the ceiling’s structural or construction elements.

Similarly, the fire resistance rating (FRR) must be at least 2 hours and the means of egress must comply with the local building code.

Also, in the case of LNG vehicles, the floors must be made of non-flammable materials that will not absorb LNG in case of a spill.

Heating, ventilation and air-conditioning

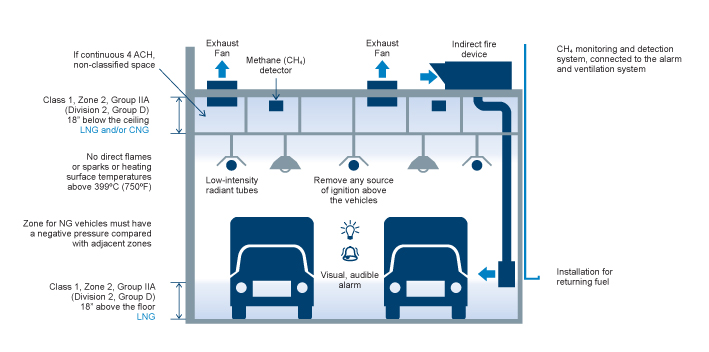

Natural gas has a flammable range of 5% to 15%, which is the percentage concentration of natural gas at which a flammable mixture can form. A methane monitoring and detection system, connected to the alarm and ventilation system, is therefore needed. The heating and ventilation equipment must be installed at least 18” below the ceiling or above the floor. Also, heating elements must not have a surface temperature above 399ºC (750ºF), or have an open flame where there is a risk of contact with natural gas.

Minimum and permanent ventilation of 4 air changes per hour (ACH) is required if there are natural gas vehicles, or non-classified electrical equipment on the ceiling. However, if the system and equipment are classified as Class 1, Zone 2, Group IIA (Division 2, Group D), then 4 ACH ventilation is not required.

An air exhaust system on the ceiling, capable of operating at a minimum of 8 ACH, connected to an alarm system and to the automatic opening of the garage doors, must be able to self-activate if the methane concentration detected is above 20% LFL. If the concentration reaches 50% LFL, the system must then disconnect all electrical and heating equipment, as well as signal evacuation of the building. The combustible gas alarm and monitoring system must be able to self-monitor and to sound an alarm in case of a malfunction.

Figure 1 illustrates the design principles for repair areas for CNG and LNG vehicles.

– Atelier d’entretien mécanique pour véhicules à gaz naturel (CNG and LNG)

1 Certificate in gas carburation techniques Class 1 or 3 (TCG-1, TCG-3).

David Ducasse, Eng.

Advisor, NGV Technologies

DATECH Group, Gaz Métro

Other reference publications

- CNGVTA: Technical Guideline for the Design and Operation of Facilities Used For Indoor Repair, Storage and Cargo Handling for Vehicles Fuelled by Compressed Natural Gas and Liquefied Natural Gas

- CAN/CSA-B108-14 (C2012): Natural Gas Vehicle and Fueling Station Installations

- NFPA 30A: Code for Motor Fuel Dispensing Facilities and Repair Garages

- NFPA 52: Vehicular Gaseous Fuel Systems Code

- NFPA 88A: Standard for Parking Structures

- DOT-FTA-MA-26-7021-96-1: Design Guidelines for Bus Transit Systems Using Compressed Natural Gas as an Alternative Fuel

- DOT-FTA-MA-26-7021-97-1: Design Guidelines for Bus Transit Systems Using Liquefied Natural Gas as an Alternative Fuel

- Informa-tech, Volume 29, No.1, March 2015

Continue reading