For horticultural and vegetable producers in Quebec, greenhouse heating represents up to 30% of their operating costs. To remain competitive, they have to reduce these costs by implementing new solutions, such as more efficient equipment, thermal screens and methods for controlling nighttime temperatures. These measures are interesting strategies for reducing their energy bill. From a perspective of increasing profitability, greenhouse producers need to balance saving energy with improving productivity. Using artificial lighting and enriching greenhouse air with CO2 accelerates plant growth by prolonging the photosynthesis periods.

Two ways to enrich greenhouse air with CO2

There are two methods for CO2 enrichment in greenhouses:

- Injection of CO2 purchased and delivered in liquid form;

- Local production of CO2 from natural gas combustion.

Two methods, four technologies

Liquid-CO2 storage tank

The process of injecting liquid CO2 into greenhouses requires a storage tank for the CO2 equipped with an integrated depressurization system to vaporize the liquid.

It is important to note that small variations in pressure can impact the distribution of the CO2 in the greenhouse.

Natural gas CO2 generator

A CO2 generator is a natural gas burner that exhausts its combustion products (CO2 + H2O vapour) directly into the greenhouse. Each cubic metre of natural gas burned produces 1.9 kg of CO2.

A CO2 generator is a natural gas burner that exhausts its combustion products (CO2 + H2O vapour) directly into the greenhouse. Each cubic metre of natural gas burned produces 1.9 kg of CO2.

CSA code B149.11 allows the use of this type of equipment provided the installed capacity does not exceed 20 BTU/hr*ft³ of greenhouse volume.

Although the heat is recovered in the greenhouse, using this equipment for heating is not recommended. In fact, the greatest need for heating is during the night when adding CO2 is not required. What’s more, injecting CO2 during the nighttime can harm the plants.

Recovery of the exhaust gases from a decentralized condensing natural gas unit

This concept of exhaust gas recovery is possible because of an exemption in Natural gas and propane installation code CSA B149.1. Article 8.9.1 requires that all appliances be connected to a chimney or vent pipe, with certain exceptions, such as in paragraph d):

| (d) for an appliance installed for the production of carbon dioxide in a greenhouse where the rate of combustion does not exceed 3 Btuh/ft3 (30 W/m3) of greenhouse volume and the concentration of carbon dioxide in the atmosphere does not exceed 5000 ppm (0.5%); and |

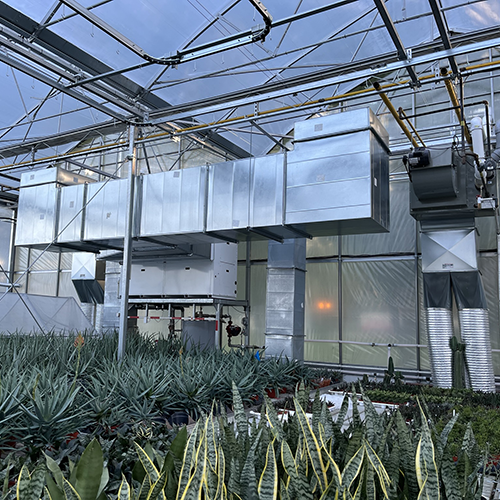

This process recovers the CO2 contained in the combustion products of a decentralized natural gas heating appliance (e.g. a unit heater) and injects it into the greenhouse as needed. When CO2 is required, a deviation valve routes the exhaust gas into the greenhouse. To maintain the same humidity level in the greenhouse during CO2 injection, use of a unit whose efficiency enables condensing is recommended given the dehumidification of the exhaust gases. Note that Gaz Métro offers financial assistance for the installation of condensing unit heaters.

Recovery of the exhaust gases from a centralized natural gas unit

High-capacity boilers exhaust combustion products that are too hot to be injected directly into a greenhouse. So a condensing recuperator is required to lower the temperature of the combustion products while condensing the water vapour resulting from the combustion. However, this can create an energy surplus. If so, it can be stored in a well-insulated buffer water tank to be used when heating the greenhouse.

Water is produced at a rate of 1.5 kg/m³ of natural gas burned and can be recovered for use in irrigation. It must be neutralized or diluted to obtain the required PH level. The rate of CO2 injection in the greenhouse depends on the type of plants grown. Since the CO2 will tend to acidify the water from the combustion products, the recuperator must be designed for a slightly acidic PH.

To distribute the thermal energy in the greenhouses, networks of hot-water pipes are the most effective for achieving a uniform temperature. The hot-water pipes also serve as rails for the carts between the rows of plants and facilitate transpiration while creating air movement around the plants. A second, moveable hot-water network, installed above the plants, can be used to heat the plant tops and control vertical growth. Finally, a third high-temperature network can be installed under the greenhouse roof, if necessary, to provide heat to melt snow and prevent accumulation.

Which solution to choose?

| Technology | Advantages | Disadvantages |

| Liquid-CO2 injection |

|

|

| CO2 generator |

|

|

| CO2 recovery from gases (Decentralized – Unit heater) |

|

|

| CO2 recovery from gases (Centralized – Boiler) |

|

|

A pilot project to inject CO2 from the gases of condensing unit heaters and modify the temperature conditions in a Gaz Métro customer’s horticultural greenhouse served to demonstrate the cost-effectiveness and potential savings of this strategy. For this project, the customer received $35,000 in financial assistance under Gaz Métro’s Innovation program.

In the final analysis, with natural gas heating appliances, each cubic metre consumed produces 1.9 kg of CO2, which customers can use to boost plant growth and significantly reduce production costs while recovering greenhouse gases for a good purpose and keeping savings from going up the chimney.

Sami Maksoud, Eng., M. Eng., MBA, CMVP®

Advisor, Energy Efficiency, DATECH, Gaz MétroCharles Côté, Eng.

Advisor, Technologies, Codes and Standards, DATECH, Gaz MétroGuy Desrosiers, Eng., CEM, CMVP

Advisor, Major Industries, Energy Efficiency, DATECH, Gaz Métro

1 Natural gas and propane installation code

![]()

Continue reading