Continue reading

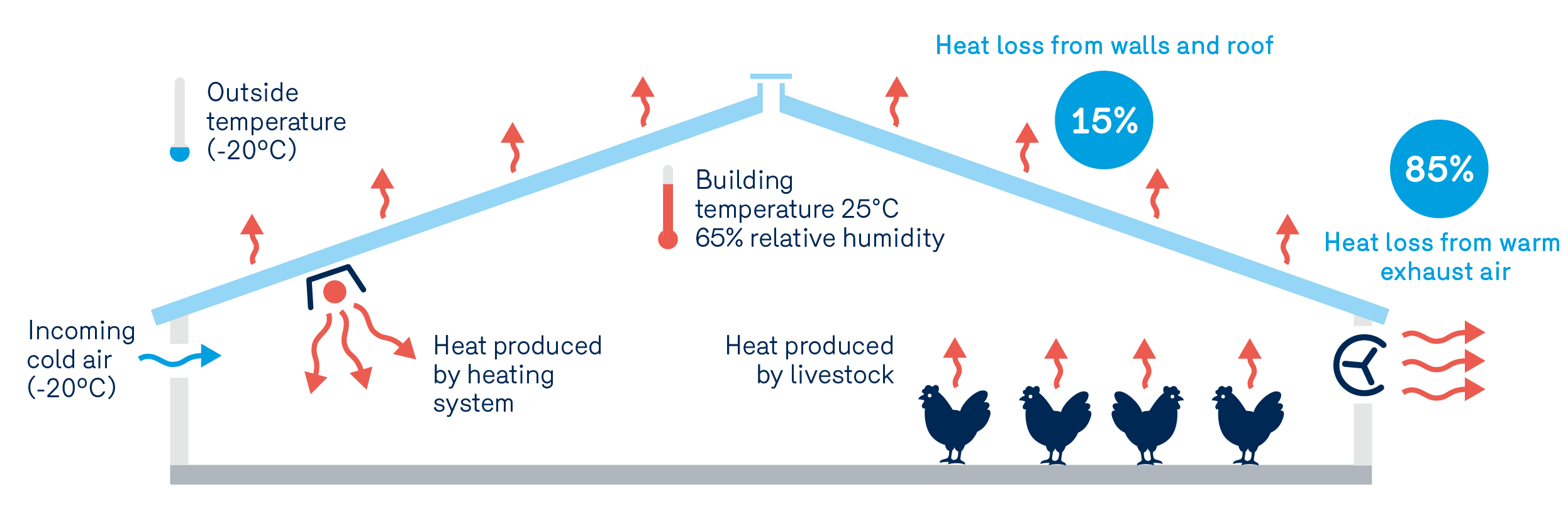

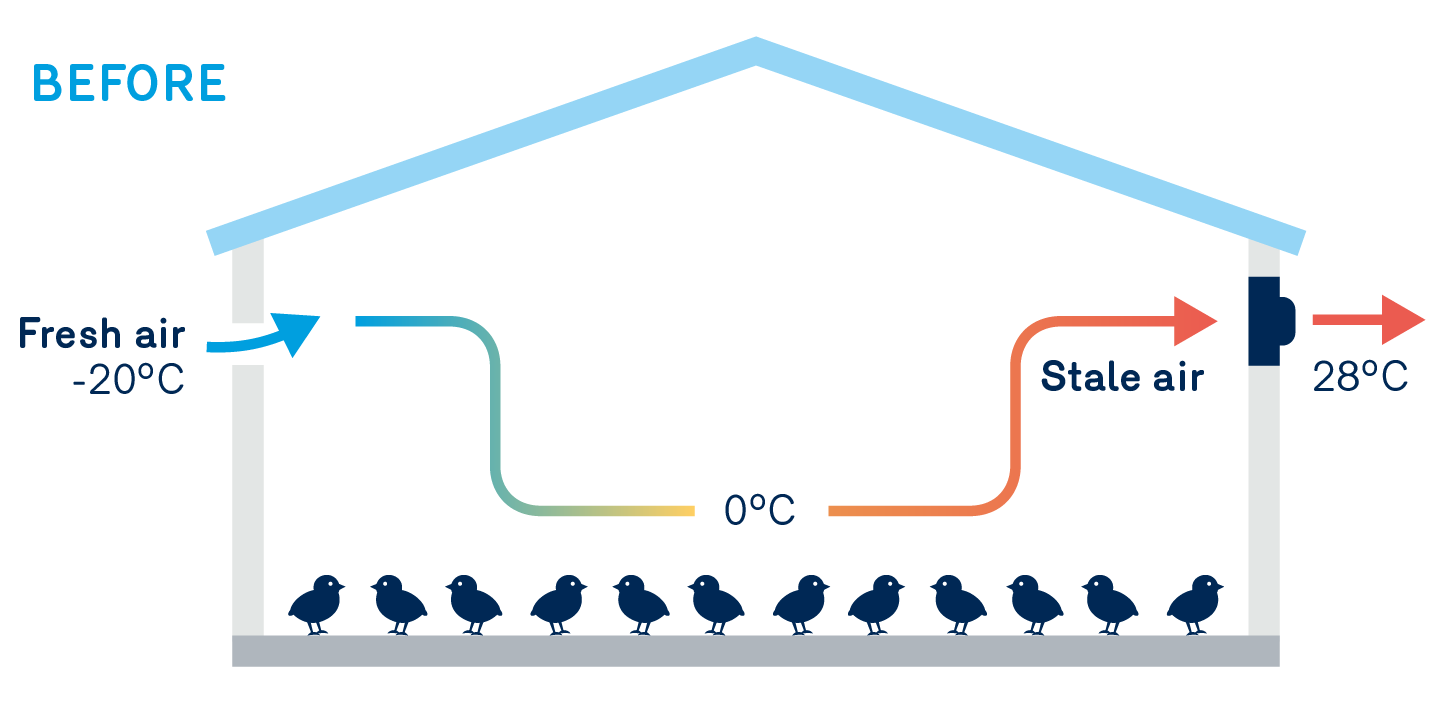

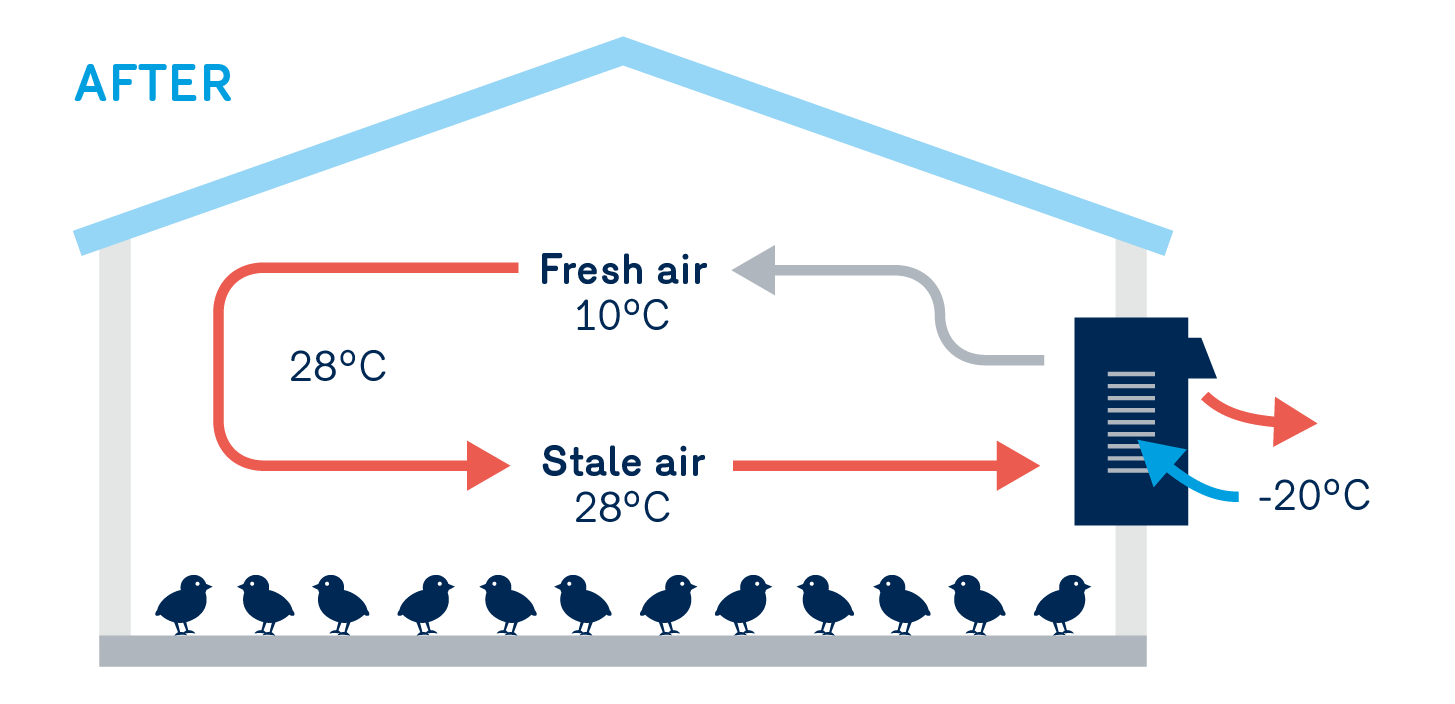

In cold weather, livestock buildings are heated to 25°C to 28°C to ensure animal comfort. But to maintain a healthy environment, indoor air must be regularly renewed by removing moisture, CO2 and ammonia. To do this, the traditional approach is to open a louvre and ventilate cold air from the outside directly into the building, then expel the stale warm air outside. This process is extremely expensive, since it requires a great deal of energy to heat the outdoor air to the right temperature. Energy loss associated with extracting indoor air can account for up to 85% of a building’s heat loss, while envelope losses are 15% (see Figure 1).

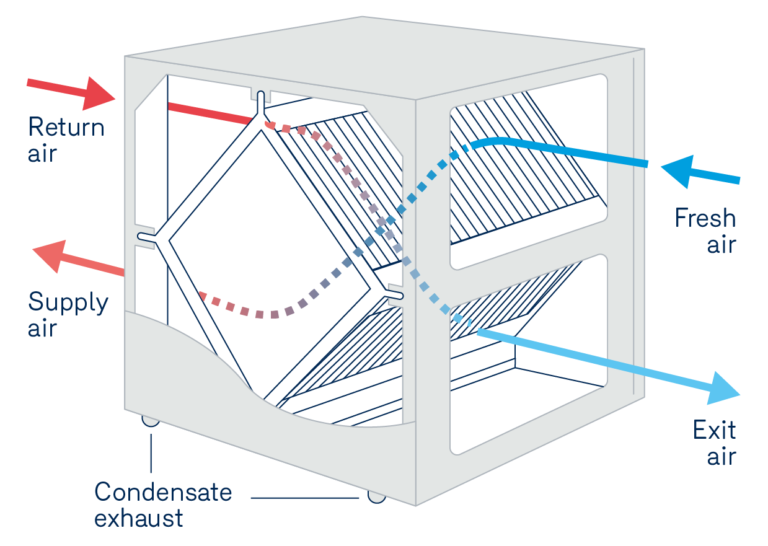

The heat exchanger (or HRV) significantly reduces these heat losses by preheating incoming air with stale air extracted from the building through a cross-flow exchanger. This solution is not new in itself. What’s innovative is the management of clogging and frost through a filtration or automatic contaminant cleaning system that maintains the performance of the exchange surface, commonly referred to as the “central module.” Typically, the exhaust air from a livestock building contains contaminants (fine dust, down, feathers, ammonia, etc.). The exchange surface therefore physically separates the exhaust air from the fresh air to prevent contamination while enabling the most efficient heat exchange possible. In addition, the central module includes an exhaust filtration system to keep the exchangers from clogging (see Figure 2).

In the central module, energy is exchanged by conduction, achieving efficiencies of 40% to 70% depending on the type of exchanger. In addition, these exchanger systems often have variable-speed drives for modulating fan speed that can be integrated into a building automation control system. These two components improve the system’s energy efficiency and optimize its operation. This technology reduces heating costs by up to 70% and greenhouse gas (GHG) emissions by up to 50% (see Figure 3).

Next-generation heat exchangers have several other beneficial features:

Today, a number of manufacturers such as ESA, Vencomatic, Orela and others make high-performance devices that are 40% to 70%** efficient—for farms of all sizes. In addition, Énergir offers a grant for the purchase of a heat exchanger as part of the Implementation of Energy Efficiency Measures componentof its energy efficiency program. This grant of $1 per m3 of gas saved, up to $1,000,000,*** significantly reduces the return-on-investment period. It’s available for all types of livestock buildings.

Heat exchangers for livestock buildings are affordable and cost-effective thanks to quick savings and financial assistance from Énergir, where applicable. Their future is bright, as their performance on the ground has shown tangible benefits for producers: reduced energy bills and GHG emissions, healthier livestock and higher revenues. As the product selection continues to broaden and improve with ever more efficient equipment, there’s every reason to believe that this technology will become more accessible in the coming years—for the greater good of the industry.

ESA: Innovation serving livestock farmingQuebec-based ESA aims to offer a simple, high-performance heating solution for poultry buildings. It was founded in 2010 thanks to support from Énergir’s energy efficiency grant program. A spinoff of a research chair at the École de technologie supérieure (ETS), ESA received an initial grant of $75,000 to prototype its ESA-1000 heat exchanger, followed by a second grant of $80,000 to demonstrate the system in a poultry house and a third grant of $150,000 for a technology showcase project to demonstrate the exchanger’s viability in three different operations (two broiler farms and one layer farm). The success of this initiative and Énergir’s financial support enabled the company to gain the confidence of key partners and continue its development, leading to the launch of the ESA-3000 heat exchanger, a more powerful and sophisticated version of the ESA-1000. Today, ESA heat exchangers can be found on a growing number of farms in Quebec and elsewhere in Canada. In 2023, for example, 170 air exchangers were installed in a dozen livestock buildings at Volailles Yamaska, an ESA customer. These projects saved the customer nearly one million m3 of natural gas and received over $700,000 in financial assistance from Énergir. For more information, read our ESA case study. Questions? Feel free to contact Mélissa Théorêt ou Cimon Desforges on the Datech team.

|

Mélissa Théorêt.

Senior Advisor, Energy expertise

Cimon Desforges

Senior Advisor, Energy expertise

Continue reading

© 2024, Énergir