The demand for alternative fuel has been growing over the past five years—despite low oil prices. The reasons are twofold: urban areas are increasingly affected by air quality problems (smog) caused by diesel vehicles, and governments have set extremely ambitious targets for reducing GHG emissions.

Natural gas for specialized vehicles (e.g. garbage trucks, intercity delivery trucks) is the most promising alternative fuel for its:

- proven technology and immediate availability;

- low emissions—15 to 25% reduction in GHGs compared to diesel, and reduced particulate emissions;

- compatibility with renewable natural gas.

The emergence of many public refuelling stations in less than a decade reflects the growing interest in this new energy. However, carriers and municipalities also welcome the implementation of private stations for better control over the price of fuel and shorter refuelling times (night refuelling).

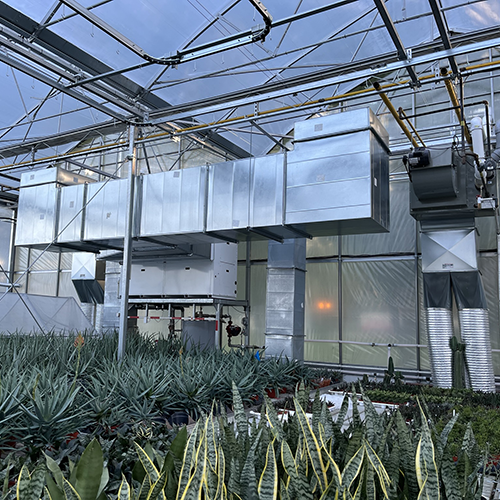

CNG station design basics

Before a carrier migrates to CNG, several steps are needed in the design process, both financially and operationally. Below are the main aspects to be considered by station designers.

1. Evaluate the number of trucks and their daily peak consumption

Carriers and municipalities must provide the designer with annual fuel consumption figures for each vehicle, incorporating the number of days per week and, in particular, the type of peak occurrence. For example, a sanitary waste disposal company’s peak consumption is July 1, given the abundance of refuse collected on moving day.

Diesel consumption history is a key element in determining the hourly flow of a station. For CNG vehicles, 1 litre of diesel is equal to approximately 1.15 m3 of natural gas under standard conditions (spark-ignition technologies).

For time-fill stations, the hourly flow required from the compressor or compressors is obtained by calculating the daily peak consumption of the vehicle fleet and the number of hours allocated by the carrier to refuel its vehicles.

For their part, fast-fill stations require storage tanks of 31.0 MPa (4,500 psi), otherwise the compressors would be oversized. For faster fill up times, a series of tanks with a sequential valve panel is recommended to take into account the pressure balance between the vehicle and the tanks.

In the event of a break or for maintenance reasons, it is preferable to have more than one compressor, unless a public station is located within a reasonable distance. Also, a fast dispenser for use by the public must be approved by Measurement Canada, and may be eligible for the new Electric Vehicle and Alternative Fuel Infrastructure Deployment Initiative.

3. Take into account integration of the Énergir system

Énergir’s distribution system must be located within a reasonable distance of the future CNG station. Interested parties must contact the commercial representative for information on the capacity and guaranteed minimum pressure. A higher pressure in Énergir’s system translates into a lower compression capacity, thus allowing savings to be made (electrical supply and lower compression capacity means a better rate for electricity).

4. Refer to code CSA B108, Part I

The operating pressure of a CNG station typically stands at 24.8 MPa (3,600 psi), while its maximum allowed pressure is 31.0 MPa (4,500 psi). Such pressure levels differ from those set out in code B149.1, with values below 400 kPa. This is why Part 1 of CSA B108 refers specifically to all the characteristics and precautions that such an installation requires, while Part 2 is dedicated to LNG stations.

5. Take into account CNG quality

While the gas in Énergir’s system is relatively dry, its humidity level (relative) increases significantly following compression. Consequently, regulator performance (including vehicle performance) may be reduced given the condensation in winter. It is therefore highly recommended to install:

- a dryer upstream of the compressors, with or without regeneration of the desiccant;

- filters placed upstream and downstream of the compressors and dryer.

6. Develop a layout plan and obtain operating permits

A layout plan must be developed to identify the locations of slow- and fast-filling areas, and to define the compression area. This area must not be located under power lines, but must be located as close as possible to natural gas services and the electrical supply. In addition, it is not uncommon for the latter to be entirely dedicated to the CNG station, since customers are making provisions for a future compression capacity with an eye to completing the conversion of their vehicle fleet.

A summary layout plan will suffice to inform the relevant authorities beforehand, such as the RBQ, the municipality and the fire department.

Economic and environmental benefits

Initially, customers can test a few vehicles at smaller CNG stations, known as mobile stations, but a critical mass of approximately 10 vehicles is recommended for implementing a private station.

Investments of $300,000 to $800,000 are planned for the station, with substantial savings anticipated with the addition of vehicles. Profitability depends on each fleet’s consumption. This can vary from 2 to 5 years compared to diesel fuel (which is prone to extremely volatile prices) when the cost is $1/litre, including subsidies under the Québec government’s Écocamionnage program.

In addition to the economic and environmental benefits, the use of CNG vehicles results in noise reduction of approximately 10 dB compared to diesel. Also, a private time-fill CNG station allows operators to save time, since they do not need to refuel their vehicles at a public diesel station.

A renewable fuel on the horizon

With renewable natural gas (RNG) on the horizon, all Énergir customers, including transit companies, will have access to carbon neutral solutions. A customer with a CNG station will be able to easily convert it to RNG, since methane is the common primary component.

Compressed natural gas can also be part of a complementary solution in the electrification of specialized transport that’s being introduced for short-distance journeys. The integration of multiple high-voltage charging stations poses certain challenges, and complementarity is certainly an asset in a collective action to eliminate the dependence on oil as quickly as possible.

Sébastien Lajoie, Eng., CEM, CMVP

Technical Advisor CNG/LNG Technologies

DATECH Group

514-598-3599

mobile 514-918-4384

[email protected]

![]()

Continue reading