Continue reading

The TubeNAD tube, developed by NADKlima, a Quebec company specializing in air diffusion technologies, is designed to ensure homogeneous ventilation and heating of large-volume buildings such as factories, warehouses and other industrial and commercial spaces. So this innovative and relatively affordable technology was particularly well suited to the needs of the Saint-Hubert plant because it prevents the stratification of ambient air and reduces heating requirements, and therefore natural gas consumption.

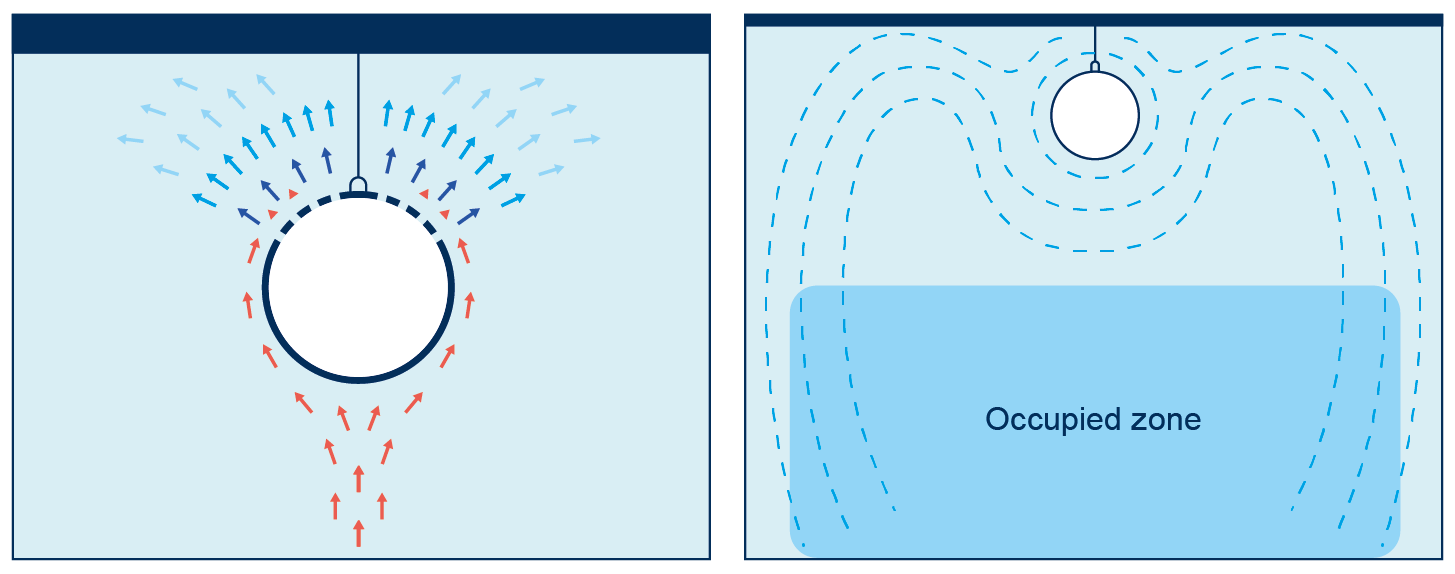

The TubeNAD tube is a fully waterproof, high-induction PVC air diffuser, with numerous holes of different diameters strategically positioned at opposed points. The number of holes and their positioning allows fresh air from the outside to be diffused without heating it. Air jets penetrate the ambient air mass at very high speeds by spinning a large amount of ambient air around themselves (Venturi effect). This movement causes turbulence that promotes heat exchange between two air masses at different temperatures. Around the TubeNAD tube, heat is exchanged between the air jets and the ambient air so their temperatures quickly equalize. This makes it possible to move air masses at the same temperature, eliminating the risk of stratification and air currents around workers.

These benefits are evident in the workplace, as employees have noticed a significant difference in the ambient temperature in the factory since the system was installed. The ambient temperature is more stable in all seasons, and air circulation has greatly improved.

As part of this energy efficiency project, the Saint-Hubert plant received $38,000 in grants under Énergir’s Energy Efficiency Measures program, which provides up to $1 per m3 of natural gas saved1. To date, the use of TubeNAD tubes has reduced natural gas consumption by 128,000 m3 while ensuring comfortable, homogeneous heating of work areas. A renovation project is also underway at the LaSalle plant, which is expected to result in additional natural gas savings of 174,000 m3 and more grants.

Since 1996, Nova Steel has been a key partner of Volvo Construction Equipment (Volvo), a world leader in the construction machinery industry, for which it manufactures buckets for power shovels and loaders. While the manufacturing of these products presents significant technical challenges, particularly for welders, it is also a source of pride and new business opportunities for the company as demand continues to grow. In recent years, the company has also started producing significant volumes of structural beams for the North American division of the Finnish company Peikko. Since then, the demand for these products has also seen notable growth in the construction sector.

However, working with industry giants like Volvo and Teikko comes with its own set of requirements, as these multinationals are often at the forefront of society’s changing priorities, particularly in the area of sustainable development and ESG policies. Volvo, for example, is a world leader in environmental strategies and aims to achieve carbon neutrality across its entire value chain by 2040. This type of decision has a direct impact on these companies’ suppliers and requires them to regularly update their operational standards to maintain these key agreements.

The advisors at Énergir’s DATECH group closely monitor changes in standards and requirements in different industries and help Énergir’s customers facing such obligations prepare for them effectively, particularly in terms of energy efficiency. The Maslow energy efficiency pyramid developed by my colleague Sami Maksoud is particularly useful for companies wishing to reduce their carbon footprint. And of course, you can contact us anytime at [email protected] to get customized solutions for your energy optimization projects.

Ann-Judith Bélanger, Eng.

Senior advisor, Energy expertise

DATECH Group

Continue reading

© 2024, Énergir