People are giving more and more attention to the fresh air needs of buildings—they’re concerned about health, and about the costs as well. Several factors are encouraging more efficient appliances, like natural gas condensing make-up air units, to emerge onto the market. Several factors are encouraging more efficient equipments, like natural gas condensing make-up air units, to emerge onto the market. The factors include the recommendations of ASHRAE Standard 62.1 (Ventilation for Acceptable Indoor Air Quality); the use of Variable Refrigerant Flow (VRF) systems in which a separate make-up air unit is normally required; and the increasing awareness of building owners, managers and users about the importance of air quality.

Eliminating barriers

While indirect-fired make-up air units have an efficiency of approximately 80%, condensing units have upwards of 90% efficiency. Despite their higher performance, however, these equipments are taking time to break into the market. Likely deterrents include a high initial purchase price and the risk of the condensate freezing in cold weather.

Through Énergir’s Innovation Program, Bousquet, one of Quebec’s largest HVAC equipment manufacturers, compared the on-site energy performance of a number of generations of make-up air units equipped with different heat exchangers, including a condensing heat exchanger. The results spoke for themselves: not only did the condensing unit prove to be more efficient, but any fears about using these equipments were dispelled.

Integrating technologies

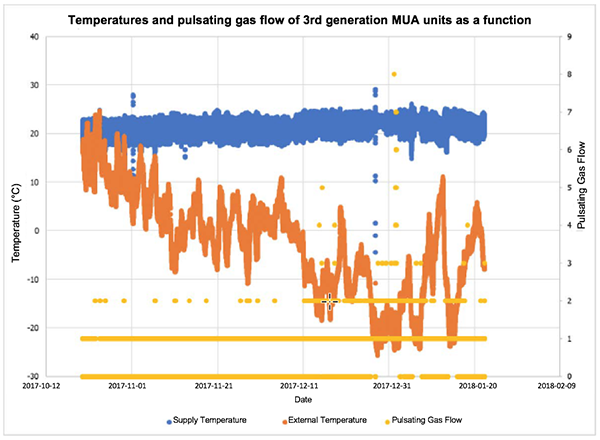

The tested condensing make-up air unit has a new heat exchanger with dimpled tubes and a larger surface that reduces static pressure by 30% compared with conventional heat exchangers. The greater surface results in improved hot air flow, while the dimpled tubes allow for a higher rate of heat transfer. The new condensing heat exchanger also works in a variable air volume (VAV) system. Finally, its parallel flow system prevents condensate from freezing (see image 2), even at very low temperatures. Furthermore, because the unit is controlled by a programmable logic controller (PLC), it is easy and quick to start up.

Full-scale testing

To demonstrate the benefits of its natural gas condensing heat exchanger, Bousquet wanted to compare its performance with that of older generation equipments. With this in mind, the company approached Énergir to carry out testing through the Innovation Program, which offers grants for innovative energy solutions (see sidebar). Following consultation, a trial was conducted under real conditions. The Natural Gas Technologies Centre (NGTC) was tasked with metering three generations of make-up air units, to compare their performances. The main objectives of the metering were as follows:

- Compare the gas consumption of each generation of appliances;

- Check the temperatures of the hot air supply and the outside air;

- Measure unit efficiency using combustion gas analyzer; and

- Ensure that there was no freezing of condensation in drains, venting systems, etc. at low temperatures during cold spells.

Promising results

Le Lalande, a grouping of 392 apartments spread over four buildings with four stories each, was an ideal site on which to conduct the comparative assessment, as the buildings were already equipped with first and second generation make-up air units manufactured by Bousquet (see image 3).

To ensure accurate test results, the condensing unit installed on the site for the testing had airflow similar to that of the existing units (5,000 cfm). Over a 12-month period (from January 2017 to January 2018), the testing revealed the following advantages to using natural gas condensing make-up air units instead of conventional units:

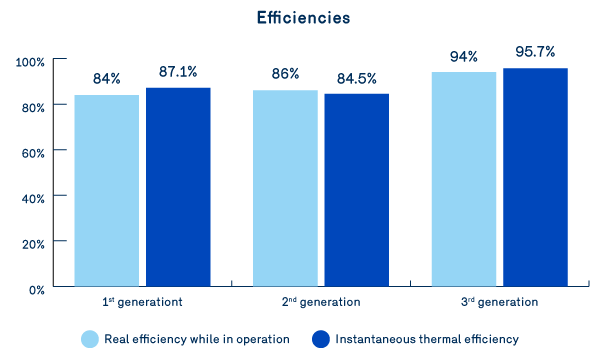

- 96% thermal efficiency compared to 87% and 84% efficiency for first and second generation units, respectively (see graph 1);

- Return-on-investment period of three to four years compared to 17 years for first generation units;

- No malfunctioning, even in very cold weather; and

- Precise temperature control promoting energy efficiency and increased comfort (see graph 2).

A winning combination of performance and versatility

With their high performance and growing availability from a number of manufacturers, these high-efficiency appliances have a promising future ahead of them. They can be adapted to the needs of many different clients and their buildings: rental units, office towers, industrial buildings, institutions, mines and more.

| Énergir’s Innovation Program at a glance Énergir’s Innovation Program aims to promote more efficient use of natural gas. It targets companies that wish to:

The grant can cover up to 75% of the costs incurred by a project, up to a maximum of $25,000 for an experimental project and up to $250,000 for a demonstration project. Through the program, Bousquet received $58,000 in financial assistance for its project, which covered 54% of costs. |

Author: Marc Francoeur, Eng., CEM, LEED PA, DATECH Chief Advisor, Technology & Innovation, Énergir

![]()

Continue reading